- British Pharmacopoeia Volume I & II

- Monographs: Medicinal and Pharmaceutical Substances

Magnesium Stearate |

|

(Ph. Eur. monograph 0229)

Excipient.

Ph Eur

Compound of magnesium with a mixture of solid organic acids and consisting mainly of variable proportions of magnesium stearate and magnesium palmitate obtained from sources of vegetable or animal origin.

- — magnesium (Mg; Ar 24.305): 4.0 per cent to 5.0 per cent (dried substance);

- — stearic acid in the fatty acid fraction: minimum 40.0 per cent;

- — sum of stearic acid and palmitic acid in the fatty acid fraction: minimum 90.0 per cent.

White or almost white, very fine, light powder, greasy to the touch.

Practically insoluble in water and in anhydrous ethanol.

First identification C, D.

Second identification A, B, D.

A. Freezing point (2.2.18): minimum 53 °C, determined on the residue obtained in the preparation of solution S (see Tests).

B. Acid value (2.5.1): 195 to 210.

Dissolve 0.200 g of the residue obtained in the preparation of solution S in 25 mL of the prescribed mixture of solvents.

C. Examine the chromatograms obtained in the assay of stearic acid and palmitic acid.

Results The 2 principal peaks in the chromatogram obtained with the test solution are similar in retention time to the 2 principal peaks in the chromatogram obtained with the reference solution.

D. To 1 mL of solution S add 1 mL of dilute ammonia R1; a white precipitate is formed that dissolves on addition of 1 mL of ammonium chloride solution R. Add 1 mL of a 120 g/L solution of disodium hydrogen phosphate R; a white crystalline precipitate is formed.

To 5.0 g add 50 mL of peroxide-free ether R, 20 mL of dilute nitric acid R and 20 mL of water R and heat under a reflux condenser until dissolution is complete. Allow to cool. In a separating funnel, separate the aqueous layer and shake the ether layer with 2 quantities, each of 4 mL, of water R. Combine the aqueous layers, wash with 15 mL of peroxide-free ether R and dilute to 50.0 mL with water R (solution S). Evaporate the organic layer to dryness and dry the residue at 100-105 °C. Keep the residue for identification tests A and B.

To 1.0 g add 20 mL of carbon dioxide-free water R and boil for 1 min with continuous shaking. Cool and filter. To 10 mL of the filtrate add 0.05 mL of bromothymol blue solution R4. Not more than 0.05 mL of 0.1 M hydrochloric acid or 0.1 M sodium hydroxide is required to change the colour of the indicator.

Maximum 0.1 per cent.

Dilute 10.0 mL of solution S to 40 mL with water R. Neutralise if necessary with nitric acid R using litmus R as indicator. Add 1 mL of nitric acid R and 1 mL of 0.1 M silver nitrate and dilute to 50 mL with water R. Mix and allow to stand for 5 min protected from light. The turbidity, if any, is not greater than that produced in a solution containing 1.4 mL of 0.02 M hydrochloric acid.

Maximum 1.0 per cent.

Dilute 6.0 mL of solution S to 40 mL with water R. Neutralise if necessary with hydrochloric acid R using litmus R as indicator. Add 1 mL of 3 M hydrochloric acid and 3 mL of a 120 g/L solution of barium chloride R and dilute to 50 mL with water R. Mix and allow to stand for 10 min. The turbidity, if any, is not greater than that produced in a solution containing 3.0 mL of 0.02 M sulfuric acid.

Maximum 3 ppm.

Atomic absorption spectrometry (2.2.23, Method II).

For the preparation of all aqueous solutions and for the rinsing of glassware before use, employ water that has been passed through a strong-acid, strong-base, mixed-bed ion-exchange resin before use. Select all reagents to have as low a content of cadmium, lead and nickel as practicable and store all reagent solutions in containers of borosilicate glass. Clean glassware before use by soaking in warm 8 M nitric acid for 30 min and by rinsing with deionised water.

Blank solution Dilute 25 mL of cadmium- and lead-free nitric acid R to 100.0 mL with water R.

Modifier solution Dissolve 20 g of ammonium dihydrogen phosphate R and 1 g of magnesium nitrate R in water R and dilute to 100 mL with the same solvent. Alternatively, use an appropriate matrix modifier as recommended by the graphite furnace atomic absorption (GFAA) spectrometer manufacturer.

Test solution Place 0.100 g of the substance to be examined in a polytetrafluoroethylene digestion bomb and add 2.5 mL of cadmium- and lead-free nitric acid R. Close and seal the bomb according to the manufacturer's operating instructions (when using a digestion bomb, be thoroughly familiar with the safety and operating instructions. Carefully follow the bomb manufacturer's instructions regarding care and maintenance of these digestion bombs. Do not use metal jacketed bombs or liners which have been used with hydrochloric acid due to contamination from corrosion of the metal jacket by hydrochloric acid). Heat the bomb in an oven at 170 °C for 3 h. Cool the bomb slowly in air to room temperature according to the bomb manufacturer's instructions. Place the bomb in a hood and open carefully as corrosive gases may be expelled. Dissolve the residue in water R and dilute to 10.0 mL with the same solvent.

Reference solution Prepare a solution of 0.0030 µg/mL of Cd by suitable dilutions of a 0.00825 µg/mL solution of cadmium nitrate tetrahydrate R in the blank solution.

Dilute 1.0 mL of the test solution to 10.0 mL with the blank solution. Prepare mixtures of this solution, the reference solution and the blank solution in the following proportions: (1.0:0:1.0 V/V/V), (1.0:0.5:0.5 V/V/V), (1.0:1.0:0 V/V/V). To each mixture add 50 µL of modifier solution and mix. These solutions contain respectively 0 µg, 0.00075 µg and 0.0015 µg of cadmium per millilitre from the reference solution (keep the remaining test solution for use in the test for lead and nickel).

Source Cadmium hollow-cathode lamp.

Wavelength 228.8 nm.

Atomisation device Furnace.

Platform Pyrolytically coated with integrated tube.

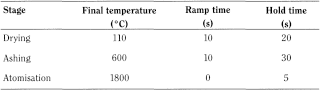

Operating conditions Use the temperature programme recommended for cadmium by the GFAA manufacturer. An example of temperature parameters for GFAA analysis of cadmium is shown below.

Maximum 10 ppm.

Atomic absorption spectrometry (2.2.23, Method II).

For the preparation of all aqueous solutions and for the rinsing of glassware before use, employ water that has been passed through a strong-acid, strong-base, mixed-bed ion-exchange resin before use. Select all reagents to have as low a content of cadmium, lead and nickel as practicable and store all reagent solutions in containers of borosilicate glass. Clean glassware before use by soaking in warm 8 M nitric acid for 30 min and by rinsing with deionised water.

Blank solution Use the solution described in the test for cadmium.

Modifier solution Use the solution described in the test for cadmium.

Test solution Use the solution described in the test for cadmium.

Reference solution Prepare a solution of 0.100 µg/mL of Pb by suitable dilutions of lead standard solution (100 ppm Pb) R with the blank solution.

Prepare mixtures of the test solution, the reference solution and the blank solution in the following proportions: (1.0:0:1.0 V/V/V), (1.0:0.5:0.5 V/V/V), (1.0:1.0:0 V/V/V). To each mixture add 50 µL of modifier solution and mix. These solutions contain respectively 0 µg, 0.025 µg and 0.05 µg of lead per millilitre from the reference solution.

Source Lead hollow-cathode lamp.

Wavelength 283.3 nm.

Atomisation device Furnace.

Platform Pyrolytically coated with integrated tube.

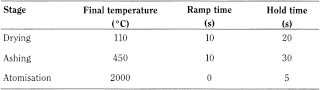

Operating conditions Use the temperature programme recommended for lead by the GFAA manufacturer. An example of temperature parameters for GFAA analysis of lead is shown below.

Maximum 5 ppm.

Atomic absorption spectrometry (2.2.23, Method II).

For the preparation of all aqueous solutions and for the rinsing of glassware before use, employ water that has been passed through a strong-acid, strong-base, mixed-bed ion-exchange resin before use. Select all reagents to have as low a content of cadmium, lead and nickel as practicable and store all reagent solutions in containers of borosilicate glass. Clean glassware before use by soaking in warm 8 M nitric acid for 30 min and by rinsing with deionised water.

Blank solution Use the solution described in the test for cadmium.

Modifier solution Dissolve 20 g of ammonium dihydrogen phosphate R in water R and dilute to 100 mL with the same solvent. Alternatively, use an appropriate matrix modifier as recommended by the GFAA spectrometer manufacturer.

Test solution Use the solution described in the test for cadmium.

Reference solution Prepare a solution of 0.050 µg/mL of Ni by suitable dilutions of a 0.2477 µg/mL solution of nickel nitrate hexahydrate R in the blank solution.

Prepare mixtures of the test solution, the reference solution and the blank solution in the following proportions: (1.0:0:1.0 V/V/V), (1.0:0.5:0.5 V/V/V), (1.0:1.0:0 V/V/V). To each mixture add 50 µL of matrix modifier solution and mix. These reference solutions contain respectively 0 µg, 0.0125 µg and 0.025 µg of nickel per millilitre from the reference solution.

Source Nickel hollow-cathode lamp.

Wavelength 232.0 nm.

Atomisation device Furnace.

Platform Pyrolytically coated with integrated tube.

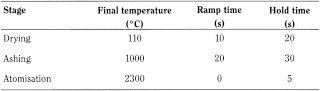

Operating conditions Use the temperature programme recommended for nickel by the GFAA manufacturer. An example of temperature parameters for GFAA analysis of nickel is shown below.

Maximum 6.0 per cent, determined on 1.000 g by drying in an oven at 105 °C.

TAMC: acceptance criterion 103 CFU/g (2.6.12).

TYMC: acceptance criterion 102 CFU/g (2.6.12).

Absence of Escherichia coli (2.6.13).

Absence of Salmonella (2.6.13).

To 0.500 g in a 250 mL conical flask add 50 mL of a mixture of equal volumes of anhydrous ethanol R and butanol R, 5 mL of concentrated ammonia R, 3 mL of ammonium chloride buffer solution pH 10.0 R, 30.0 mL of 0.1 M sodium edetate and 15 mg of mordant black 11 triturate R. Heat at 45-50 °C until the solution is clear and titrate with 0.1 M zinc sulfate until the colour changes from blue to violet. Carry out a blank titration.

1 mL of 0.1 M sodium edetate is equivalent to 2.431 mg of Mg.

Gas chromatography (2.2.28): use the normalisation procedure.

Test solution In a conical flask fitted with a reflux condenser, dissolve 0.10 g of the substance to be examined in 5 mL of boron trifluoride-methanol solution R. Boil under a reflux condenser for 10 min. Add 4 mL of heptane R through the condenser and boil again under a reflux condenser for 10 min. Allow to cool. Add 20 mL of saturated sodium chloride solution R. Shake and allow the layers to separate. Dry the organic layer over 0.1 g of anhydrous sodium sulfate R (previously washed with heptane R). Dilute 1.0 mL of the solution to 10.0 mL with heptane R.

Reference solution Prepare the reference solution in the same manner as the test solution using 50.0 mg of palmitic acid CRS and 50.0 mg of stearic acid CRS instead of the substance to be examined.

- — material: fused silica;

- — size: l = 30 m, Ø = 0.32 mm;

- — stationary phase: macrogol 20 000 R (film thickness 0.5 µm).

Carrier gas helium for chromatography R.

Flow rate 2.4 mL/min.

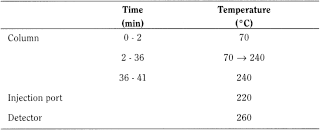

Temperature:

Detection Flame ionisation.

Injection 1 µL.

Relative retention With reference to methyl stearate: methyl palmitate = about 0.9.

System suitability Reference solution:

- — resolution: minimum 5.0 between the peaks due to methyl palmitate and methyl stearate;

- — relative standard deviation: maximum 3.0 per cent for the areas of the peaks due to methyl palmitate and methyl stearate, determined on 6 injections; maximum 1.0 per cent for the ratio of the areas of the peaks due to methyl palmitate to the areas of the peaks due to methyl stearate, determined on 6 injections.

This section provides information on characteristics that are recognised as being relevant control parameters for one or more functions of the substance when used as an excipient (see chapter 5.15). Some of the characteristics described in the Functionality-related characteristics section may also be present in the mandatory part of the monograph since they also represent mandatory quality criteria. In such cases, a cross-reference to the tests described in the mandatory part is included in the Functionality-related characteristics section. Control of the characteristics can contribute to the quality of a medicinal product by improving the consistency of the manufacturing process and the performance of the medicinal product during use. Where control methods are cited, they are recognised as being suitable for the purpose, but other methods can also be used. Wherever results for a particular characteristic are reported, the control method must be indicated.

The following characteristics may be relevant for magnesium stearate used as a lubricant in tablets and capsules.

Determine the specific surface area in the P/Po range of 0.05 to 0.15.

Sample outgassing 2 h at 40 °C.

Ph Eur